Make your labels stand out

Hot or cold foil is an embellishment process used in the printing industry to make labels and products more distinct and attractive to the customer. The process can also be used to apply security features.

Hot foil

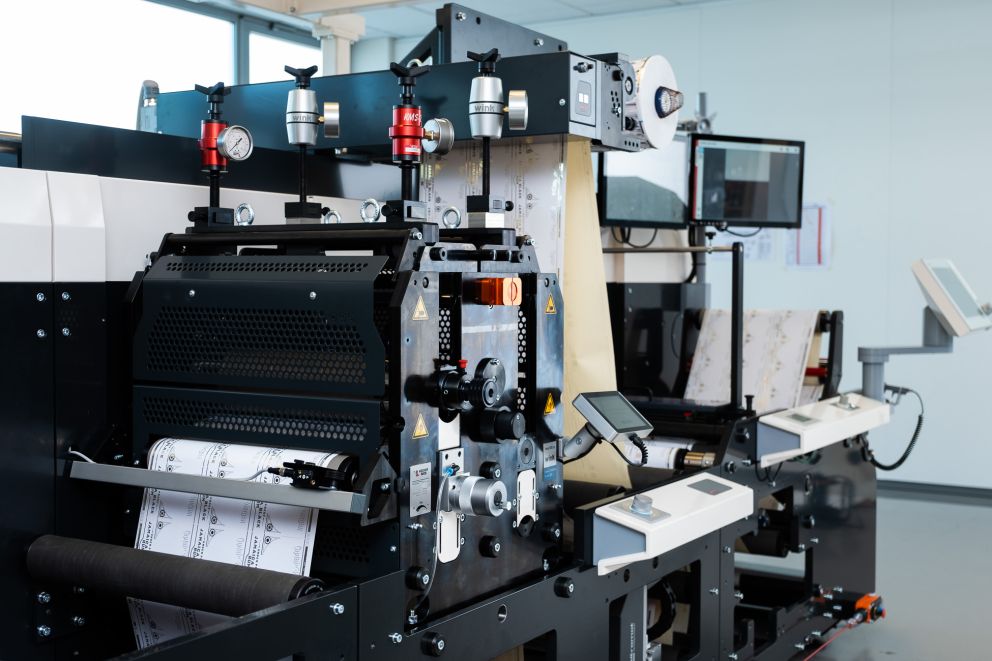

The flexible positioning hot foil unit is simple to use and does not interfere with press flexibility by tying up a print unit when in use. It essentially provides you with an extra colour.

Benefits of the hot foil unit are higher production speeds, eccentric fine tuning of stamping tension during printing that provides the operator on-the-run setting adjustments, and the use of full width foil cylinders and segmented engraved rings.

Cold foil

The cold foil application process is relatively new compared with hot foil but offers the same look using a different process.

This is done using a flexographic printing unit which applies an adhesive using a heavier anilox. Different thicknesses of adhesive are required depending on the image and image size, e.g.: for broad areas, a lower line count is needed.

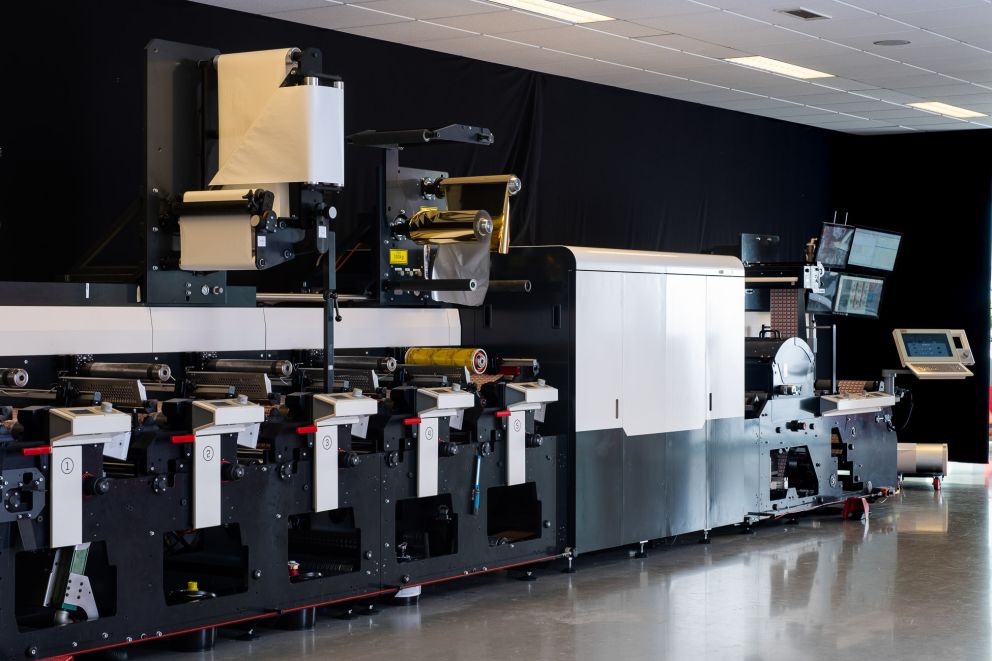

Machines suitable for hot and cold foiling

Building on the acclaimed MPS EF narrow

web press series, the EF Packaging Press

extends capabilities to flexible packaging and

shrink sleeve applications with an impressive

26” web width, opening new opportunities

for label converters and flexible packaging

businesses.

the flexible packaging solution

www

Speak with our specialist

Do you have aquestion about one of our presses? Wondering if our machines can accommodate a special application? Looking for more information about our MPSConnect connectivity services and performance improvements? Whatever you need, our team of print experts are here to assist you.

.jpg?width=3100&mode=crop&format=jpeg&signature=e869002e6dcdeedd13df0516decdbed5fcee1a7c)