Continuous improvement is in our DNA

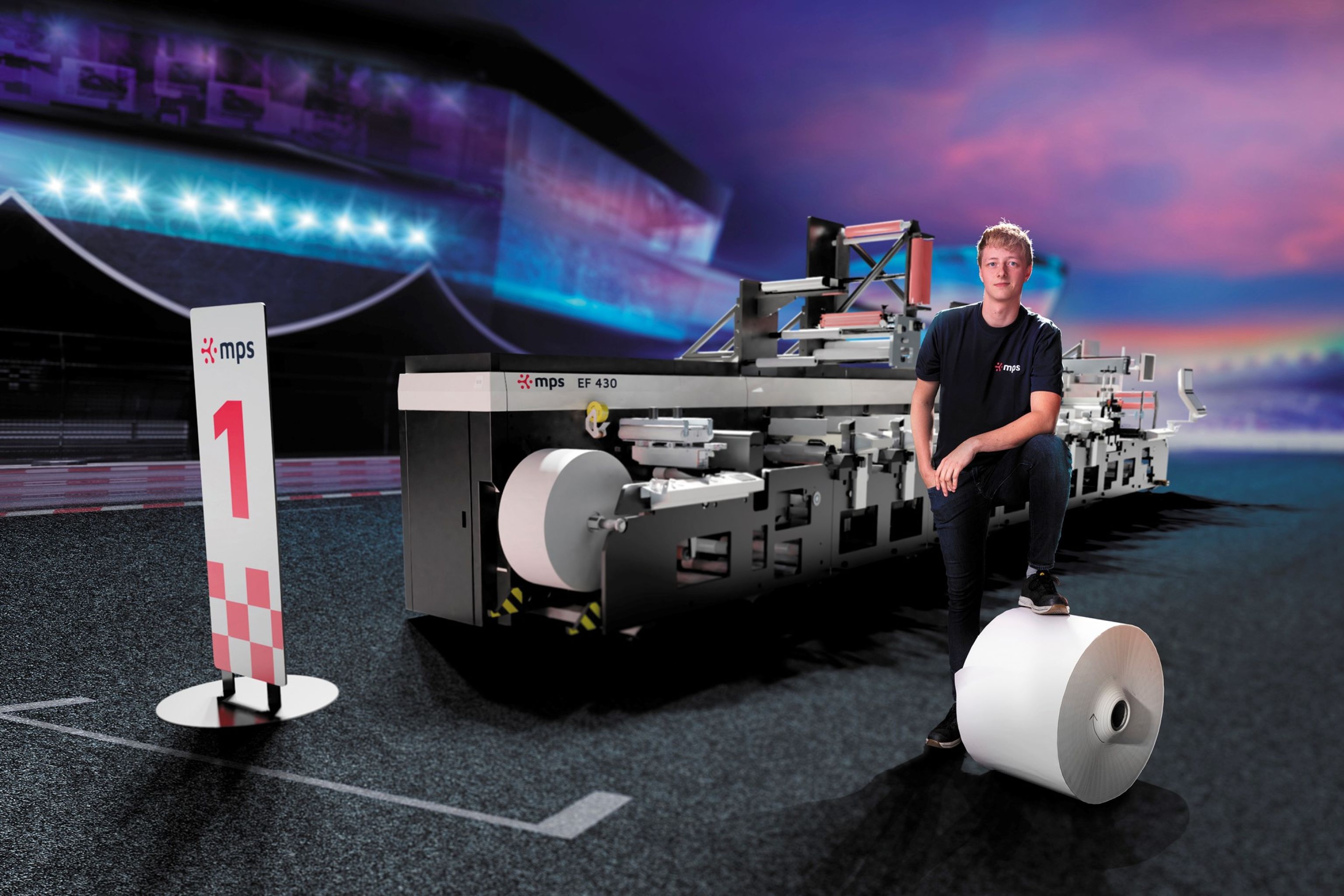

The EF next generation is a robust, reliable, highly qualified and fully automated flexo printing press ready for 24 x 7 operations.

- Robust Engineering

- Two levels of automation

- Improved and new features

- Ultimate in press productivity through connectivity

Added Values

- Connectivity and performance improvements with MPSConnect

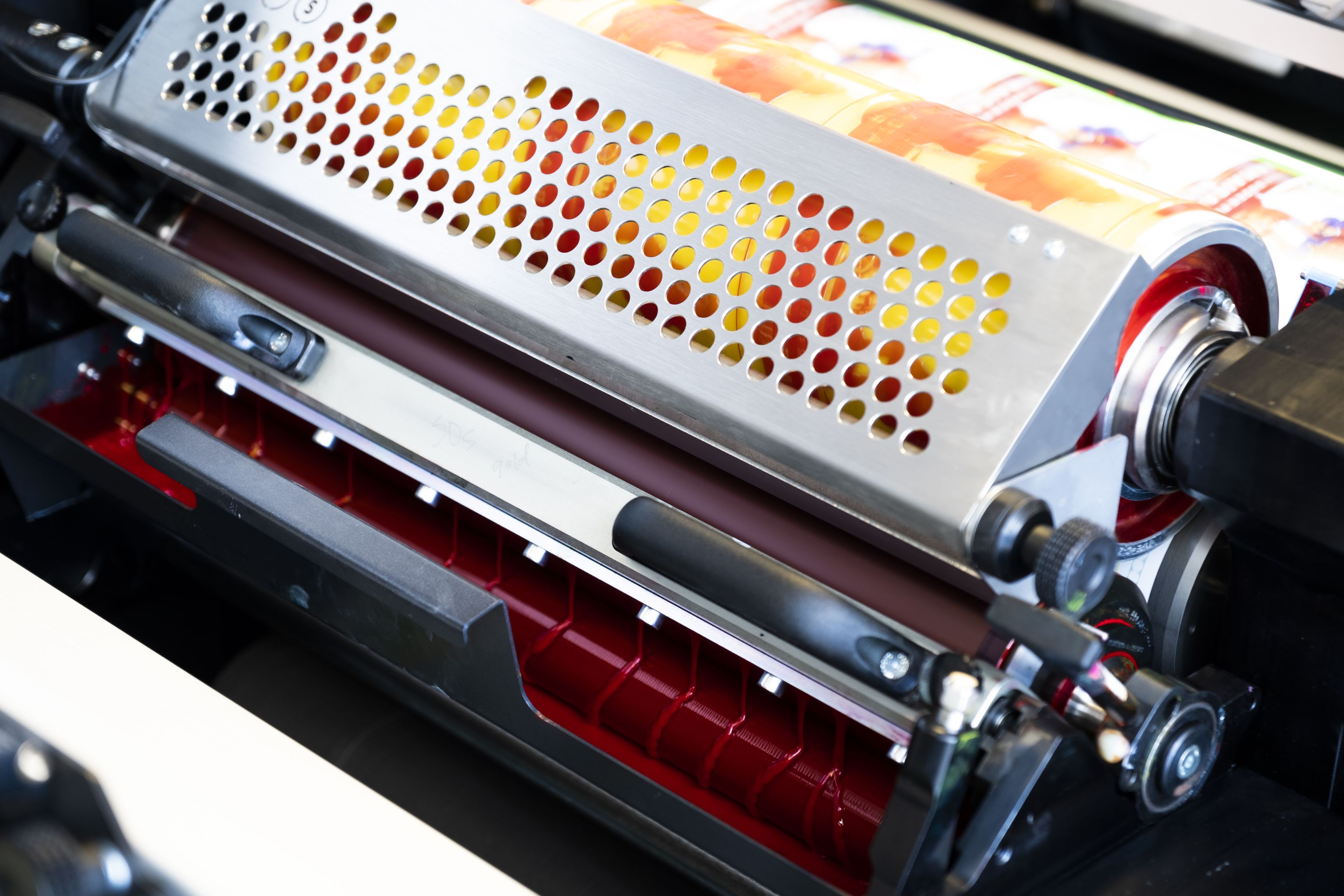

- Excellent print quality

- High productivity

- Suitable for multiple substrates

- Easy to operate

- Flexible converting

- Flexibility in automation

- Lowest cost price per 1000 labels

- High repeatability with automated pressure settings

Unique Features that drive your EF press

Non-stop print change

Crisp.Dot Technology

iStrip Matrix

iControl

Ultraflex Railsystem

Auto-Teach Pre-Register

Improved Features for your maximum performance

To help you unleash your printing potential and get maximum results from your press, we keep on innovating.

Based on the successful foundation of 6 previous EF platform generations, we made these improvements to the next generation EF machine:

-

Standard slide out ink drawer

E-sleeve with quick release

Advanced Job Memory

M2M (Mark-to-Mark) Register

Extended web width to 680mm

-

Improved robust rail units

Standard finger bar safety protection

Ergonomic improvements

MPSConnect: Pole position with the EF Next generation press

New and improved features of the EF plus the collection and analysis of performance data through MPSConnect and Performance Programs, drive your success formula for profit.

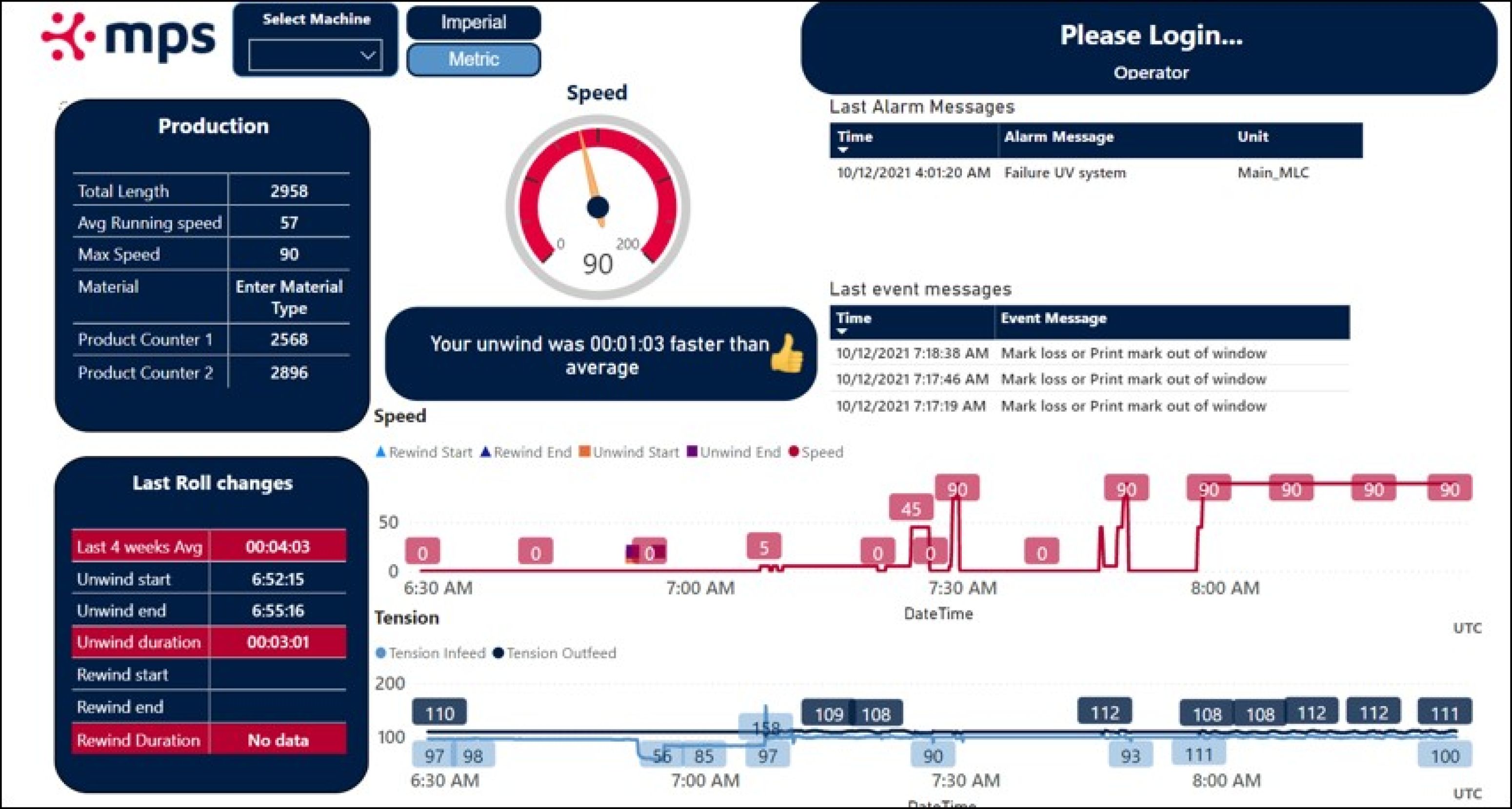

With MPSConnect, we dive into your printing press and see exactly what’s happening. Our sensor technology combined with the internet (IoT) makes real-time data collection possible.

From valuable 24x7 fact-based insights, our team of experts help you make continuous performance improvements in waste, speed, and uptime to increase your competitive advantages and maximize your profits.

New Features for even better performance and output

For the ultimate in press productivity, we added these new features to the EF platform:

-

MPSConnect

-

Operational Dashboard

-

Management Dashboard

-

User Management & Personalized Performamce

For more information and specifications of the EF next generation press, download the brochure.

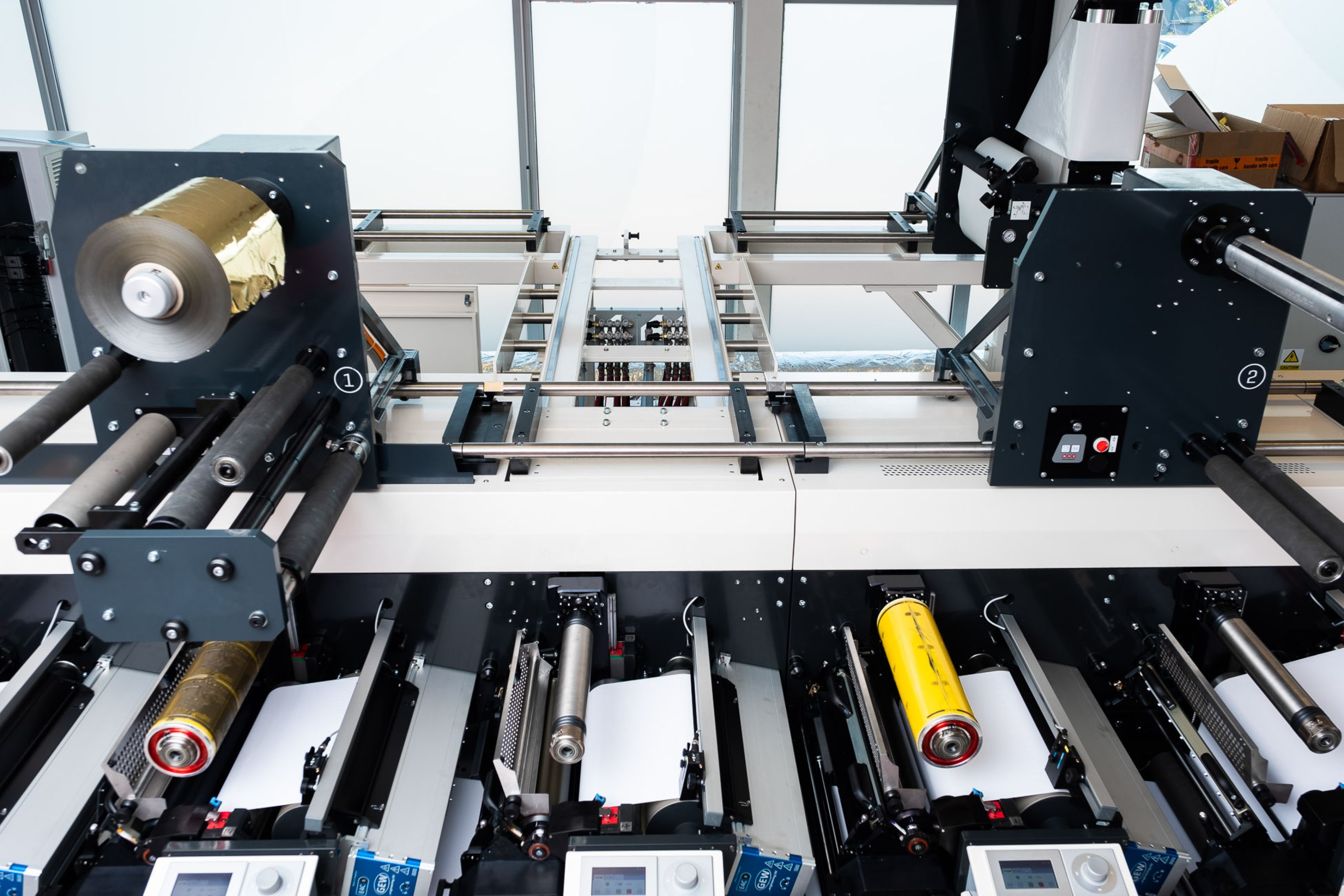

Options

Converting units can be implemented at any location along the EF next generation press using the Ultraflex Rail System. With an ergonomic design, the rail units (including foiling, web turner bar, screen printing, etc.) are easy to move and quick to change positioning at different print stations.

Speak with our specialist

Do you have aquestion about one of our presses? Wondering if our machines can accommodate a special application? Looking for more information about our MPSConnect connectivity services and performance improvements? Whatever you need, our team of print experts are here to assist you.