Revolutionizing Plate Mounting

FlexoMatrix® is a game-changer in flexo plate mounting, designed to enhance precision, speed, and efficiency. By fully automating the mounting process, FlexoMatrix® eliminates common errors like misalignment and air bubbles, ensuring superior print quality and reducing waste.

Seamless Integration with MPS Technology

FlexoMatrix® works seamlessly with MPS presses to optimize your entire printing process. When paired with MPS equipment, FlexoMatrix® ensures that plate mounting is not only accurate but also perfectly aligned with the press’s auto-register systems. This synergy enhances overall print quality and operational efficiency, making sure every job change is executed flawlessly.

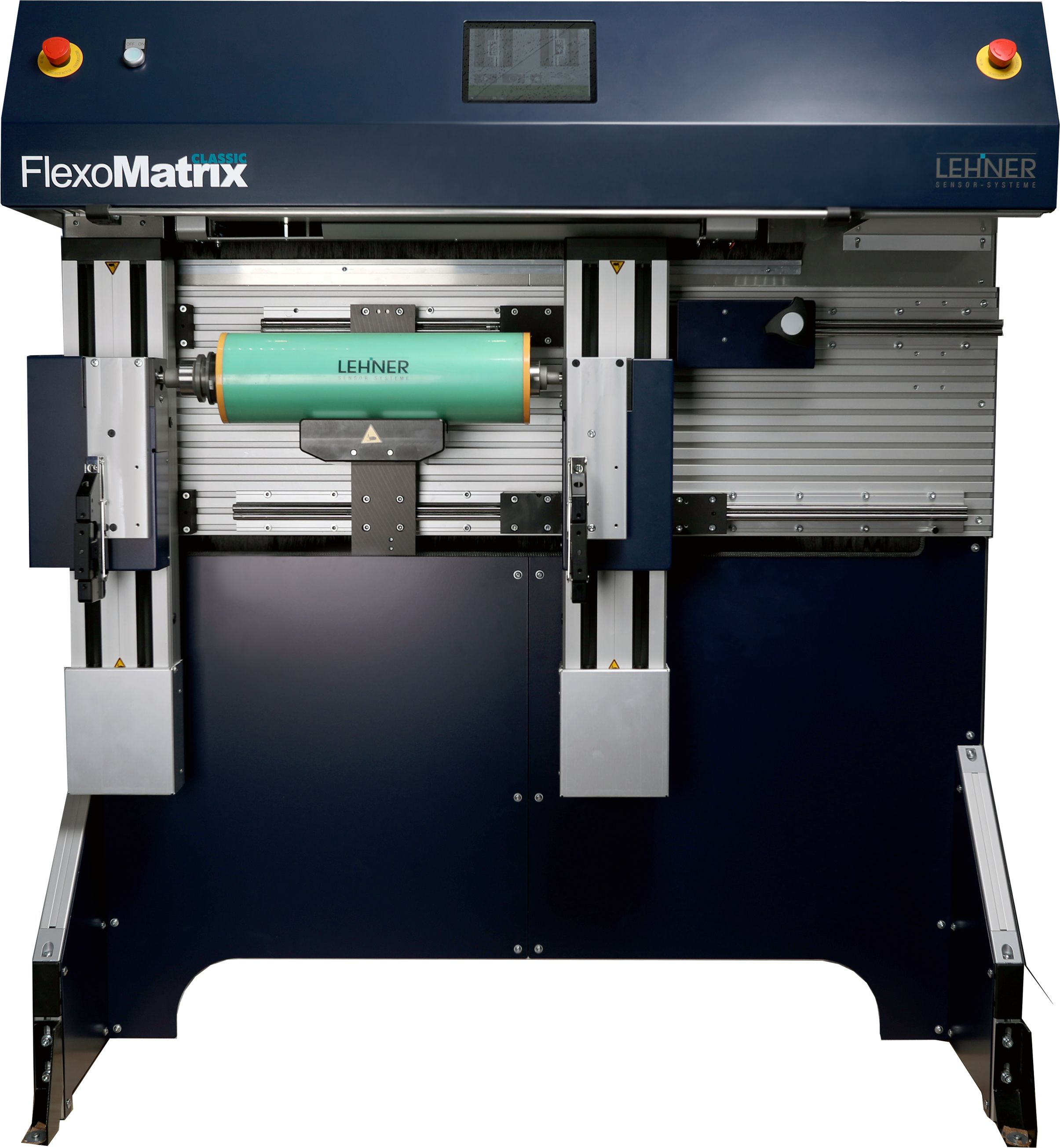

FlexoMatrix Classic

FlexoMatrix Professional

FlexoMatrix Robotics

Speed and Precision

FlexoMatrix® delivers plate mounting in under 90 seconds with a precision tolerance of +/- 0.03mm. This rapid setup reduces downtime and accelerates job changes, allowing you to maximize the performance of your MPS press. The system’s automated process guarantees consistent results, regardless of operator experience, which is crucial for maintaining high-quality output across multiple jobs.

Minimized Waste and Increased Profitability

By cutting pressroom waste by up to 50% with each job change, FlexoMatrix® helps lower operational costs and improve profitability. The system’s accuracy and efficiency also reduce the risk of customer complaints and reprints, contributing to a more cost-effective and reliable production process.

Versatile Solutions for Every Print Shop

FlexoMatrix® offers scalable solutions from entry-level systems to advanced robotic setups, fitting seamlessly into your existing print workflow. Its compatibility with various cylinder, sleeve, and plate types ensures that it meets the diverse needs of modern print shops.

MPS Systems benefits from the FlexoMatrix professional and its flexibility. With the adaptors the MPS E-sleeves can be mounted perfectly and with the air mandrel we can mount air sleeves when needed to print during our demos.

Rapid Return on Investment

FlexoMatrix® provides a quick return on investment, typically within 12-18 months, thanks to its ability to reduce waste, shorten setup times, and improve print quality. Its integration with MPS technology amplifies these benefits, making it an essential tool for any print shop looking to enhance its efficiency and output.

The company LEHNER and

MPS share the ambition of providing their customers with comprehensive, smart

solutions for greater efficiency in conventional flexographic printing. Modern

flexographic printing is much more than the organization of prepress, press,

and postpress. Modern printing companies are characterized by workflows that

link all work areas together and activate synergies. Both companies, MPS and

LEHNER, offer system solutions that provide their customers with unique selling

points, leading to greater success in flexographic printing. - Lars Lehner,

CEO Lehner

MPS provides the best Flexo printing machine on the market to ensure the best print quality. Because the quality of the print goes beyond just having the best machine on the marked MPS partnered with Lehner to ensure that plate mounting will never have a negative effect on the print quality. The FlexoMatrix is a user friendly, quick, and highly accurate automatic plate mounter that will ensure the best result with every plate mounted. With the FlexoMatrix you will never have to remount plates due to skew plates saving valuable down time of the printing machine. - Jordy van der Aa, Print Application Specialist MPS Systems